Discovering Cutting-edge Production with In-Mold Decorations

Discovering Cutting-edge Production with In-Mold Decorations

Blog Article

Understanding In-Mold Decorations: Approaches, Trends, and Ideal Practices for Optimal Outcomes

In the world of production, the art of in-mold decors stands as a pivotal facet of item layout and manufacturing. In-Mold Decorations. By delving into the strategies, fads, and best techniques that underpin effective in-mold decoration procedures, services can unlock a world of opportunities that not just raise the aesthetic appeal of their products yet additionally enhance manufacturing effectiveness and boost customer involvement.

Material Selection

Material selection is an essential element of grasping in-mold designs, as it straight affects the quality and resilience of the end product. When picking products for in-mold designs, it is vital to take into consideration aspects such as compatibility with the molding process, the desired visual result, and the ecological conditions the item will certainly deal with. Thermoplastic products like abdominal, polycarbonate, and polypropylene are typically used for in-mold decors as a result of their adaptability and capability to achieve complex styles. These products provide outstanding moldability, enabling makers to create intricate shapes and patterns with accuracy.

Additionally, products with high warmth resistance are preferred for in-mold designs, specifically for items that will certainly be exposed to elevated temperatures throughout their lifecycle. By thoroughly picking the ideal product for in-mold decors, suppliers can boost the total quality and toughness of their items, satisfying the expectations of both end-users and clients - In-Mold Decorations.

Design Advancement

A crucial consider progressing the area of in-mold designs is the constant exploration and implementation of style development techniques. Layout technology plays a critical function in improving the visual charm, functionality, and total top quality of products manufactured making use of in-mold decor procedures. By including ingenious design components, makers can differentiate their products in the market, bring in consumers, and remain in advance of competitors.

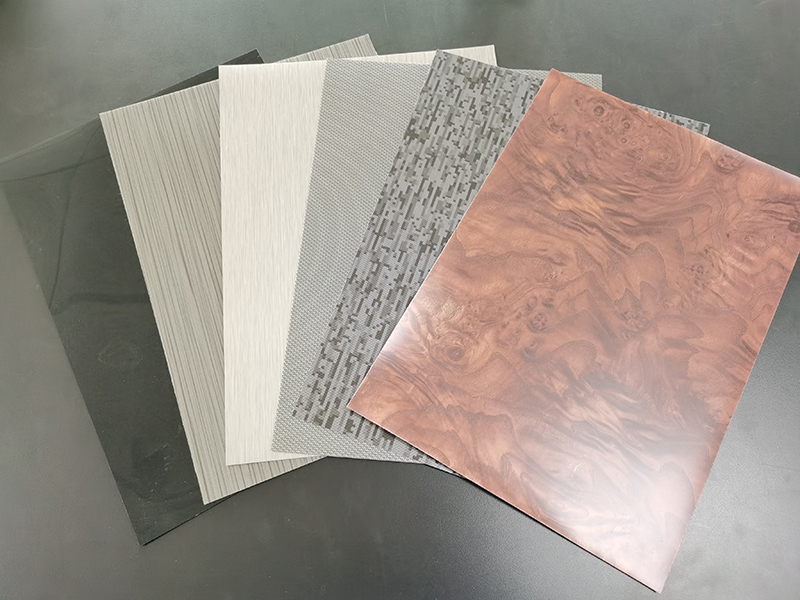

Among the key aspects of style advancement in in-mold decorations is the assimilation of elaborate patterns, textures, and graphics that were previously testing to achieve with typical design methods. Advanced modern technologies such as 3D printing and digital layout tools make it possible for designers to develop complicated and detailed styles that can be seamlessly moved onto molded components. In addition, the use of vivid colors, metal finishes, and unique effects like gloss or matte structures can better raise the aesthetic appeal of in-mold decorated items.

Additionally, layout development prolongs beyond appearances to include useful enhancements such as ergonomic shapes, incorporated attributes, and customizable elements that satisfy details user requirements. By welcoming design development, suppliers can unlock brand-new opportunities for creativity, personalization, and product distinction in the affordable landscape of in-mold decorations.

Production Performance

Effective manufacturing processes are important for translating the cutting-edge layouts established in the field of in-mold decorations right into high-grade completed products that fulfill market needs and consumer assumptions. In the world of in-mold decorations, production performance includes various vital facets that add to the overall success of the manufacturing process.

Automation not just increases the manufacturing process but also improves accuracy and repeatability, leading to an extra consistent and high-quality end product. On the whole, an alternative technique to manufacturing effectiveness is vital in making best use of the potential of in-mold decor methods and accomplishing ideal outcomes in the competitive market landscape.

Top Quality Control Measures

What are the vital techniques for guaranteeing strict quality assurance measures in the realm of in-mold decors? Quality assurance actions are extremely important in in-mold decor procedures to make sure the production of high-grade and flawless ended up items. One important technique is the implementation of strenuous assessment procedures at every phase of the production process. This entails carrying out comprehensive aesthetic assessments, dimensional checks, and color consistency analyses to determine any inconsistencies or issues beforehand.

Utilizing innovative technologies such as computerized assessment systems can likewise boost the quality control process by giving accurate and trusted information for analysis. These systems can spot blemishes that may be missed by hands-on examinations, thus enhancing overall item quality and consistency.

Regular training and advancement programs for staff members associated with the in-mold decoration process can additionally add to preserving high-quality standards. By informing personnel on ideal practices, quality expectations, and the relevance of focus to detail, companies can promote a culture of high quality awareness throughout useful content the organization.

Consumer Charm

To improve the marketability of in-mold decoration products, providing and comprehending to consumer choices play a crucial function in determining their allure and success. Using customization alternatives such as individualized designs, shade variations, and textural elements can substantially enhance the charm of in-mold decoration items.

Conclusion

In-mold designs provide a reliable and functional means to boost item aesthetics. Understanding in-mold designs needs a holistic strategy that takes into consideration all facets of the production process to ensure success.

In the world of production, the art of in-mold decorations stands as a pivotal facet of product design and production. Layout advancement plays an important role in boosting the aesthetic allure, performance, and general high quality of items produced using in-mold decor processes.One of the vital elements of layout development in in-mold decorations is the assimilation of intricate patterns, appearances, and graphics that were previously testing to achieve with standard decoration techniques.Efficient manufacturing procedures are necessary for translating the ingenious layouts established in the field of in-mold decors into high-grade finished items that fulfill market demands and customer assumptions. Supplying customization choices such as tailored designs, color variants, and textural elements can considerably boost the charm of in-mold decoration products.

Report this page